|

|---|

节能干燥设备--(真空)带式干燥机 (可做欧盟CE & PED认证)

Energy Saving Drying Equipment --Vacuum Belt Dryer ( Can be CE&PED certificated )

真空带式干燥机

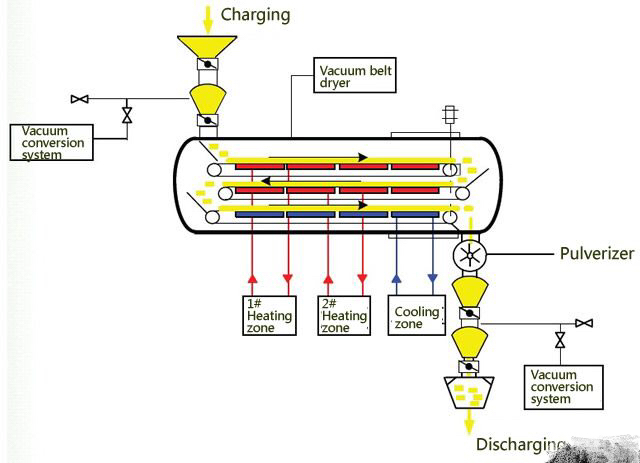

真空低温固体连续干燥机,在真空容器内设计布置3-11层传送带,通过连续固体进料器和布料器,将客户所需要干燥的原料在真空条件下实现连续送料,并均匀的布放在干燥带上,由于物料在干燥过程中不断翻动,加快了蒸发速度和时间,同时保证产品在干燥过程中的均匀性,干燥的温度在 30℃-150℃ 可调,物料从进入干燥机到干燥后出料约 20-80 分钟可调。干燥后的产品如需粉碎工艺,可在真空条件下粉碎,避免了粉尘飞扬,增加了产品收率和解决了污染等问题。干燥后的产品通过真空连续出料器和真空收料机实现连续出料,同时可实现有机溶剂的回收,解决了环保问题并增加溶剂回收收益。 干燥原理 根据客户产能的大小,在真空容器内设计布置3-11层传送带,通过连续固体进料器和布料器,将客户所需要干燥的原料在真空条件下实现连续送料,并均匀的布放在干燥带上,由于物料在干燥过程中不断翻动,加快了蒸发速度和时间,同时保证产品在干燥过程中的均匀性,干燥的温度在30-150℃可调,物料从进入干燥机到干燥后出料约20-80分钟可调。干燥后的产品如需粉碎工艺,可在真空条件下粉碎,避免了粉尘飞扬,增加了产品收率和解决了污染等问题。干燥后的产品通过真空连续出料器和真空收料机实现连续出料,同时可实现有机溶剂的回收,解决了环保问题并增加溶剂回收收益。 适用范围 ◆中药、西药、食品、化工等企业 |

Vacuum belt continuous dryer

Vacuum continuous solid-state dryer with 3-11 layers in the vacuum container. Through the continuous solid feeder and distributor, the raw materials needed by customers can be continuously fed under vacuum conditions, and the uniform cloth can be placed on the conveyor. On the drying belt, as the material is continuously turned during the drying process, the evaporation speed and time are accelerated, and the uniformity of the product during the drying process is ensured. The drying temperature is adjustable from 30°C to 150°C, and the material goes from the dryer to the dryer. The output is adjustable after about 20-80 minutes. After the dried product needs to be crushed, it can be crushed under vacuum conditions to avoid flying dust, increasing product yield and solving problems such as pollution. The dried product is continuously discharged through the vacuum continuous feeder and the vacuum receiver. At the same time, the organic solvent can be recovered, the environmental protection problem is solved, and the solvent recovery benefit is increased. Drying principle According to the size of the customer's production capacity, the 3-11 layer conveyor belt is designed and arranged in the vacuum container. Through continuous solid feeders and distributors, the raw materials needed by customers can be continuously fed under vacuum conditions, and the uniform cloth can be placed dry. With the belt, as the material is continuously turned during the drying process, the evaporation speed and time are accelerated, and at the same time, the uniformity of the product during the drying process is ensured. The drying temperature is adjustable at 30-150° C., and the material goes from the dryer to the dryer. The material is adjustable in about 20-80 minutes. After the dried product needs to be crushed, it can be crushed under vacuum conditions to avoid flying dust, increasing product yield and solving problems such as pollution. The dried product is continuously discharged through the vacuum continuous feeder and the vacuum receiver. At the same time, the organic solvent can be recovered, the environmental protection problem is solved, and the solvent recovery benefit is increased. Scope of application ◆Chinese medicine, western medicine, food, chemical industry, etc. |

4.工艺流程图schematic diagram

5.技术参数( Technical Parameter ):

参数\型号Parameter\Model |

VBD6.5-3 |

VBD15-3 |

VBD30-5 |

VBD50-5 |

VBD80-5 |

VBD100-7 |

VBD120-7 |

VBD160-7 |

VBD200-11 |

VBD220-11 |

加热面积Heating Area |

6.5 |

15 |

30 |

50 |

80 |

100 |

120 |

160 |

200 |

220 |

有效水分蒸发量Effective moisture evaporation(Kg/h) |

5~10 |

10~20 |

25~35 |

40~60 |

70~90 |

90~120 |

110~130 |

150~180 |

180~210 |

210~230 |

换热板层数Number of heat exchange plates |

3 |

3 |

5 |

5 |

5 |

7 |

7 |

7 |

11 |

11 |

干燥温度范围Drying temperature range |

40~180 |

|||||||||

加热及冷却区分配Configuration of Heating and cooling area |

2/1 |

2/1 |

4/1 |

4/1 |

4/1 |

6/1 |

6/1 |

8/1 |

10/1 |

10/1 |

进料含水率Raw Moisture content |

20~30 |

|||||||||

干燥成品含水率Final moisture content |

≤1~4 |

|||||||||

加热介质Heating media |

热水Hot Water、蒸汽Steam、导热油Hot oil |

|||||||||

设备尺寸mesurements(L/W/H)mm |

6500/1200/2200 |

6500/1900/2500 |

9500/1900/2500 |

12000/2200/2800 |

12000/2600/3000 |

12500/2600/3000 |

17500/2600/3000 |

17500/3000/3200 |

17500/3200/3200 |

19500/3200/3200 |

总装机功率Total power |

18 |

24 |

30 |

34 |

36 |

40 |

45 |

48 |

50 |

58 |

清洗系统工作压力Washing working pressure(MPa) |

0.5~1 |

|||||||||

干品产量Capacity |

30~60 |

60~100 |

100~150 |

150~220 |

200~300 |

250~350 |

300~400 |

350~450 |

400~600 |

500~800 |

注明Remark |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Contact:

|

Name: Mr.Jack Chen , Cell Phone : 0086-138-0611-9207 , Email: donautech@126.com Address: Shen'an Industry zone ,Zhenglu Town , Changzhou City ,Jiangsu Province , China . |

Name: Ms.Emily Zha, Cell Phone : 0086-137-7510-5518 , Email: Emilyzha@126.com Address: Shen'an Industry zone ,Zhenglu Town , Changzhou City ,Jiangsu Province , China . |

CHANGZHOU DONAU TECH CO., LTD.

CHANGZHOU DONAU TECH CO., LTD.