|

|---|

节能干燥设备--反刍动物饲料流化床包衣机(可做欧盟CE & PED认证)

Energy Saving Drying Equipment --Ruminant feed fluidized bed coater ( Can be CE&PED certificated )

反刍动物饲料、添加剂及药品的流化床包衣机

1、概述 流化床包衣是在流化过程中,所有的颗粒都悬浮在流化气流中,表面完全暴露,可以喷 射各种包衣液, 并进行湿热交换。喷嘴的安装方式一般有三种,顶喷、侧喷、底喷,根据不同的工艺要求选择不同的喷液位置。流化气体可以使用惰性气体。亦可闭路循环。 2、包衣原理 种子颗粒在高速气流中处于流化状态,包衣液体通过喷嘴雾化后与流化状态的颗粒接触,在颗粒表面形成固化的膜,有些包衣液是由硬脂酸、棕榈酸等常温固化物料组成,则在包衣过程中要先通过高温将该包衣材料熔化成液体,并通过全程保温将其喷射到颗粒表面,冷却后即可得到包裹好的颗粒。有些膜需要一边喷一边用热风蒸发掉水分,液体膜中的水分蒸发掉后,变成固体膜包裹在颗粒表面。 3、适用范围 粉体、颗粒、丸掩味、防潮、防氧化、防水、防热、着色隔离等包衣 |

Fluid bed coating machine for ruminant animal feeds, additives and medicines

1.Overview In the fluidized bed coating process, all the particles are suspended in the fluidized gas stream and the surface is completely exposed. Various coating solutions can be sprayed and the heat and moisture exchanged. There are generally three types of nozzle installation methods, top spray, side spray, and bottom spray. Different spray positions are selected according to different process requirements. Fluidizing gas can use inert gas. It can also be closed loop. 2. coating principle The seed particles are in a fluidized state in a high-speed air stream. The coating liquid is atomized through the nozzles and comes into contact with the particles in the fluidized state. A solidified film is formed on the surface of the particles. Some of the coating liquids are cured by room temperature such as stearic acid and palmitic acid. In the material composition, the coating material is first melted into a liquid by a high temperature during the coating process, and is sprayed onto the surface of the particles through full heat preservation, and the wrapped particles can be obtained after cooling. Some membranes require the use of hot air to evaporate water while spraying. The moisture in the liquid film evaporates and becomes a solid film that wraps around the surface of the particles. 3. the scope of application Powder, particle, pill taste, moisture, oxidation, waterproof, heat, color isolation and other coating |

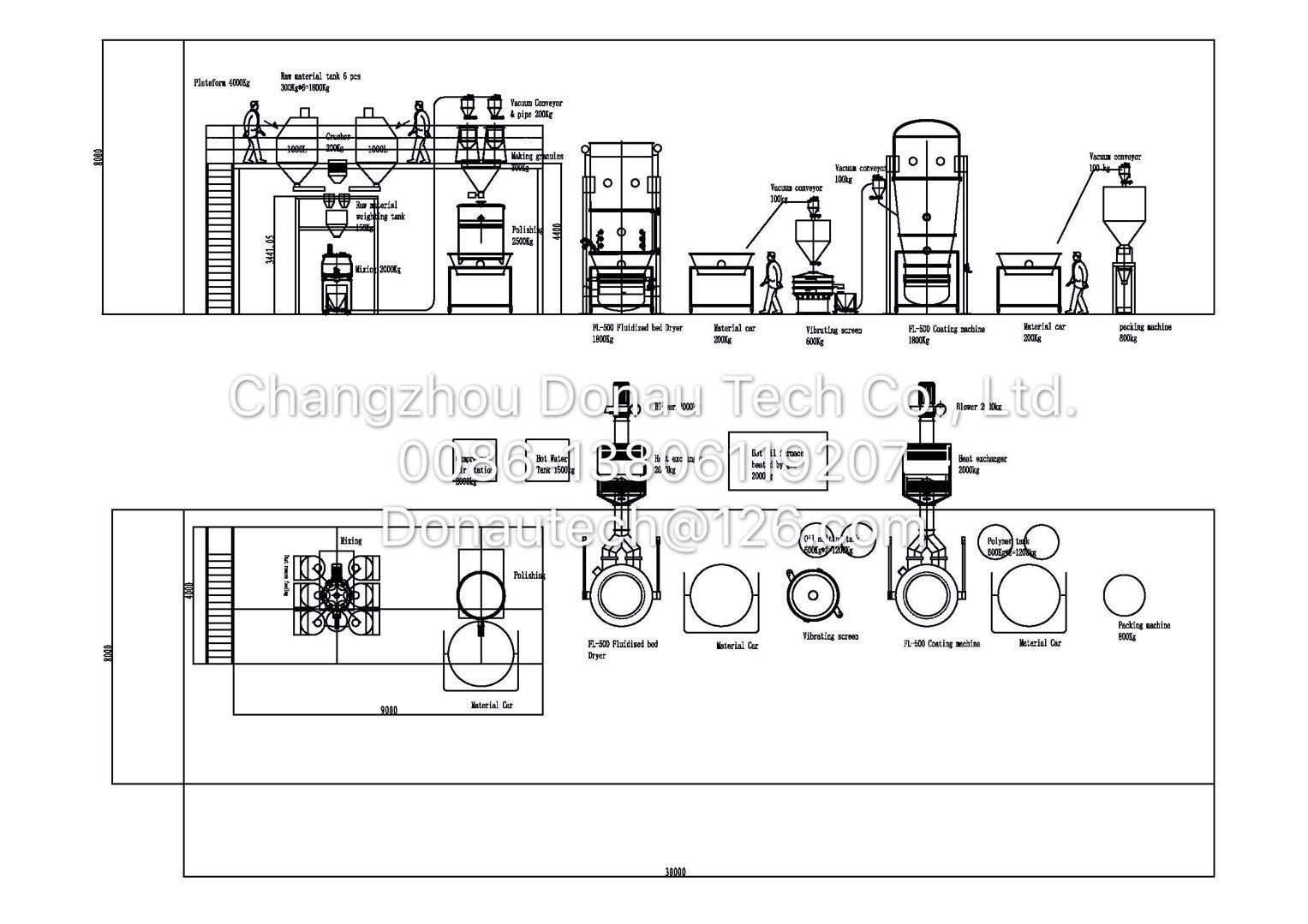

4.工艺流程图schematic diagram

5.技术参数( Technical Parameter ):

ltem Specification |

5 |

15 |

30 |

60 |

120 |

200 |

300-800 |

||

Capacity |

kg/batch |

4-6 |

10-20 |

25-40 |

40-80 |

80-150 |

150-250 |

By client |

|

Container volume |

L |

15 |

50 |

100 |

220 |

360 |

650 |

||

Power of fan |

Kw |

4 |

5.5 |

7.5 |

15 |

18.5 |

22 |

||

Compressed air |

Pressure |

Mpa |

|

|

0.6 |

|

|

||

Consumption |

m3/min |

0.4 |

0.6 |

0.9 |

1.3 |

1.8 |

2.4 |

||

Steam |

Pressure |

Mpa |

|

|

0.4-0.6 |

|

|

|

|

Consumption |

Kg/h |

9Kw |

64 |

85 |

181 |

250 |

330 |

||

Contact:

|

Name: Mr.Jack Chen , Cell Phone : 0086-138-0611-9207 , Email: donautech@126.com Address: Shen'an Industry zone ,Zhenglu Town , Changzhou City ,Jiangsu Province , China . |

Name: Ms.Emily Zha, Cell Phone : 0086-137-7510-5518 , Email: Emilyzha@126.com Address: Shen'an Industry zone ,Zhenglu Town , Changzhou City ,Jiangsu Province , China . |

CHANGZHOU DONAU TECH CO., LTD.

CHANGZHOU DONAU TECH CO., LTD.